N360 and N330 are continuously variable planetary (CVP) transmissions that revolutionize your shifting experience. These transmissions provide a smooth, continuous progression from one ratio to another, with no abrupt ratio changes or harsh gear engagements. Compared with complex conventional internally geared hubs, the NuVinci Optimized hub is based on a very simple concept, which withstands high torque and power levels from eBike drivetrains and is virtually maintenance free. Instead of many complex gears and components, the NuVinci technology is based on a set of rotating, tilting spheres fitted between two rings. Unlike conventional transmissions that have a fixed number of gear ratios, our continuously CVP drivetrain has an unlimited numberof ratios within its wide 360% (N360) or 330% (N330) range.

Arizona designer/bike: ”Hubs are great on streets, can be tuned for low hill climbing but on longer technical uphill trails can easily hit thermal limits. I am stating the results of a few years and almost $100k in experimentation. A heavy, non geared motor just doesn’t belong in the rear end of an off road performance vehicle, with the tech that’s currently available. Until the tech necessary to significantly reduce motor and controller mass catches up, small&efficient motors with variable gearing will be the way to go. I’ve put a couple thousand reliable miles on a bike with 8+kw continuous, 24kw peak that weighed 75 lbs and could stomp anything from 5mph uphill technical to 56mph on the flats. The drive train test mule would hit 56 miles per hour in 6 seconds and still pull all but the steepest, most technical trails, mainly due to traction/wheelie limits. At this gearing, it would get hot after about 2 miles of 6% grade and it had a single crown fork and bicycle wheels and tires, so I regeared it for 42mph. In gravel with a 260lb veteran Baja racer on it, it could go from 3mph-42mph in 3 seconds. I used a cycle analyst v3 to tune the throttle and it was perfect controllable. My shoulders could only hang on to riding that thing for half an hour at a time. Range was between 15-80miles depending on pedal input, 25 miles average on smooth ground, 30mph. I know that the drivetrain is rock solid and ready for a custom frame.

Arizona designer/bike: ”Hubs are great on streets, can be tuned for low hill climbing but on longer technical uphill trails can easily hit thermal limits. I am stating the results of a few years and almost $100k in experimentation. A heavy, non geared motor just doesn’t belong in the rear end of an off road performance vehicle, with the tech that’s currently available. Until the tech necessary to significantly reduce motor and controller mass catches up, small&efficient motors with variable gearing will be the way to go. I’ve put a couple thousand reliable miles on a bike with 8+kw continuous, 24kw peak that weighed 75 lbs and could stomp anything from 5mph uphill technical to 56mph on the flats. The drive train test mule would hit 56 miles per hour in 6 seconds and still pull all but the steepest, most technical trails, mainly due to traction/wheelie limits. At this gearing, it would get hot after about 2 miles of 6% grade and it had a single crown fork and bicycle wheels and tires, so I regeared it for 42mph. In gravel with a 260lb veteran Baja racer on it, it could go from 3mph-42mph in 3 seconds. I used a cycle analyst v3 to tune the throttle and it was perfect controllable. My shoulders could only hang on to riding that thing for half an hour at a time. Range was between 15-80miles depending on pedal input, 25 miles average on smooth ground, 30mph. I know that the drivetrain is rock solid and ready for a custom frame.

I know all about the inefficiency and waste of the capitalist structure. When people see a big travel bike, some are going to push its limits. The BB is a great example of this. I see big travel, fat knobbies, and I think, that would be a blast to fling down some hills. Being an engineer though, I know for a fact that the hub motor simply can’t handle some of the uses the styling and other components suggest. Consumers aren’t aware of this stuff and will beat these bikes into the ground. A large percentage won’t ride hard but they’ll read the critical reviews of the guys that do.”

With the 42T/22T combo I could climb 20-degree grades with ease and still get darn close to 30 mph on the flats (but RPM’s at top speed were too fast to comfortably pedal along with). electricbike-blog.com/nuvinci-n380-the-bbs02-weve-got-the-biggest-balls

With the 42T/22T combo I could climb 20-degree grades with ease and still get darn close to 30 mph on the flats (but RPM’s at top speed were too fast to comfortably pedal along with). electricbike-blog.com/nuvinci-n380-the-bbs02-weve-got-the-biggest-balls

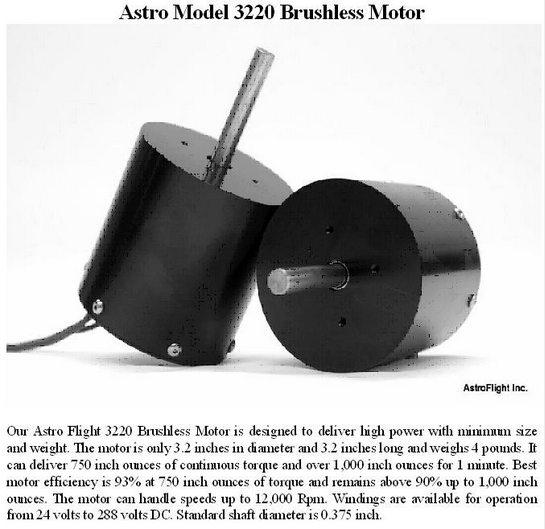

”In the bike I mentioned in the forum, I used the 3220 for the engine. In that bike, the nuvinci n360 was mounted in the rear wheel. The e-drive drove it through the disc brake mount and couldn’t use its gearing. Because of this, the 3220 would get hotter than I liked on long steep uphills. If I had driven the input of the wheel mounted nuvinci with 8kw, it would have exceeded its torque rating. When mounted in the frame, it can be geared to spin much faster, reducing the torque it “sees”, then a final reduction to the rear wheel would get the torque back. The bike that houses the NuVinci in frame, makes use of all of the previously tested components, connects them via efficient and low maintenance belts, and houses them all inside a force ventilated, pressurized frame, only exists in piles of cad drawings right now. The monocoque frame simultaneously housing components and providing mounting locations for jackshafts , the nuvinci, and the motor does the job of being the frame and locating everything. I can’t wait for Free Open Source Virtual Prototyping Environments to happen.”

”As far as belt drives go, once you try one, you’ll never look back to loud, maintenance prone chains. Manufacturers use these belts as timing belts on engines and they regularly transmit 20hp+ for hundreds of thousands of miles. They’ve completely replaced chains for that application. The secret to longevity is enclosing them so they stay clean. A baja secret is very slightly pressurizing the enclosure to keep even fine dust out. Everything in my designs has been adapted from other industries that have been using the ideas successfully for years so development and testing wouldn’t be as big of a hurdle as one would think.

”As far as belt drives go, once you try one, you’ll never look back to loud, maintenance prone chains. Manufacturers use these belts as timing belts on engines and they regularly transmit 20hp+ for hundreds of thousands of miles. They’ve completely replaced chains for that application. The secret to longevity is enclosing them so they stay clean. A baja secret is very slightly pressurizing the enclosure to keep even fine dust out. Everything in my designs has been adapted from other industries that have been using the ideas successfully for years so development and testing wouldn’t be as big of a hurdle as one would think.

The special/possibly patentable ideas for my ultimate ebike project are the morph on the fly variable geometry frame and seat height, seat frame/shock setup, 4 link active brake pivot rear suspension that follows the same angle axle path as the fork and has no chain or wheelbase growth, fully enclosed, pressurized monocoque frame and swingarm to keep dust out of the belt drives, and the way the pedal drive meets the e-assist to reduce stress on the transmission while matching pedal cadence to motor speed. There are a few other little tricks as well like a mechanical throttle/brake override/anti whiskey throttle setup, custom lipo parallel blocks and a mechanically adjustable u/v/w encoder for the Astro 3220 motor in case a suitable sensored controller ever comes out. As far as collaboration on the ultimate ebike project goes, I’m happy to share the dxf’s showing all angles and x/y/z parts location, dxf’s I have of other custom parts, parts list, and a comprehensive description of a pedalable, bunnyhoppable, sub 75lb, 8″ travel bike with on the fly adjustable seat height and frame geometry adjustment, 1.25kwh of lipo, and a 1lb motor that can handle 8kw for at least 15 minutes at a time and peaked at 24+kw on tarmac dragrace starts. All anyone interested in producing it, would have to do is use the dxf’s showing the location of all the components as basis for 3d modeling to design the frame, or adapt things I’ve shared into current designs, and you’d have a bike that will outperform anything out there. I’d only ask that if someone uses any or all of the ideas to significantly increase profits or grow the company that you donate a tiny percentage to my non profit endeavor.

There are lots of bikes with the same motor/esc/display/reduction/batteries on the forum but no one’s put the NuVinci CVP transmission in the frame in an all enclosed, belt drive setup. I’d just freely share everything but I’ve got lots of resources and time into this project and would like to see some kind of return for it. I guess the ball is in the field of anyone interested in the designs. The videos and walk around of the test bike are posted here: youtube.com/CampExist”

PS: ”The BHT bike is beautiful! Definitely the most interesting one I’ve seen so far. Just looking at the models, from my e-bike research and experience, and experience as a downhiller, I would change a few small things. Stuff like 8mgt belt or 219 o-ring to the rear and in frame mounted gearing. I despise derailleurs, mainly constantly repairing them for the large majority of riders that can’t seem to understand that it’s best to let off the power before shifting, whether it’s leg power or motor power, well, that and ripping them off constantly on rocks and roots.”